Ambient Air Heated Vaporizer

LIN, LOX, LAR, LNG, LH2, LCO2 & LN2O

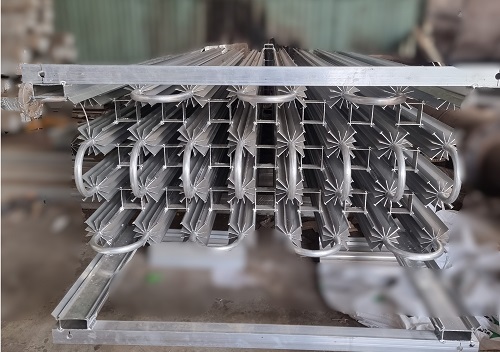

Aluminium Extruded Fin Star Type Ambient Air Heated Vaporizer are used to Vaporizer the Cryogenic & Non-Cryogenic Liquid in to gaseous form without giving any External Energy. Cryogenic liquid are produced at liquefaction plants and transported to end customers. This liquid are then vaporizer/Re-gased for different industrial and commercial application. In Warmer countries ambient heat is available 24 X 365 Days. This Free Energy is used for Vaporization therefore it is also called as Natural Draft Cryogenic Vaporizer. The Design Temperature is -196°C to +50°C. As aluminium is good conductor to heat and temperature so we used it for vaporization. Aluminium 6061 T6 and 6063 T5 are used for material of construction to manufacture a vaporizer. Moreover this comes with no external energy on it works with ambient temperature and in Vertical & Horizontal orientation with and without frame. This Vaporizers are easy to use and Ambient Air Heated Vaporizers ae of Two Types as below.

- Low Pressure Vaporizer Range up to 90 Kg/Cm2 with aluminium bends welded with the aluminium star fins to provide the out pressure.

- Capacity of the Vaporizer is 50 Nm3/hr to 5000 Nm3/Hr. and above that we can used by putting bank of Vaporizer.

- Operating Fluids LIN, LOX, LAR, LCO2, LH2, LHe & LNG and many more cryogenic and non-cryogenic liquids.

- Design Codes ASME, USTAMP

- FIN modulation 8 fin and 12 fin are precisely placed in different heated zones for maximised modular Vaporization.

- Frame Construction for Big Vaporizer above 800 Nm3/Hr will be aluminium alloy 6061 T6, SS 304, SS316 and CS on Request.

- Bank of Vaporizer are kept to use in series or parallel for higher flow and more duty cycle.

- High Pressure Vaporizer Range from 150 Kg/Cm2 up to 400 Kg/Cm2 with SS/CU bends expanded with aluminium star fins to provide the output also known as SS/CU Lined Vaporizer.

- Capacity of the Vaporizer is 100 Nm3/Hr. to 1000 Nm3/Hr. and above on request.

- Operating Fluids LIN, LOX, LAR, LCO2, LH2, LHe & LNG and many more cryogenic liquids.

- Design Codes ASME, USTAMP

- FIN modulation 8 fin and 12 fin are precisely placed in different heated zones for maximised modular Vaporization.

- Two or More Vaporizer are systematically clubbed to operate in series or parallel for higher flow rate and duty Cycles.